Let's be honest – most procurement guides give you the same recycled advice about finding "the cheapest supplier" and "getting quotes from multiple vendors." But after years of working in Indian sourcing, we've uncovered some game-changing secrets that procurement consultants charge thousands to reveal.

Here's what they don't want you to know.

Secret #1: The "Relationship First" Rule That Trumps Everything

While everyone's obsessing over price negotiations, the smartest buyers know that relationships are your real competitive advantage.

Most procurement teams make the mistake of treating suppliers like commodities. They send RFQs to dozens of vendors, pick the cheapest one, and wonder why quality drops or deliveries get delayed.

Here's what actually works: Start building relationships before you need them. The best Indian suppliers are already working with their preferred clients when you come knocking. By the time you're urgently looking for a supplier, you're competing for their leftover capacity.

Smart buyers spend time understanding their supplier's business, their challenges, and their growth plans. They visit facilities (even virtually), meet key personnel, and position themselves as partners, not just customers.

Secret #2: The Hidden Verification System Nobody Talks About

Everyone knows to check certifications and references, but there's a deeper verification system that separates the pros from the amateurs.

The 3-Layer Verification Method:

Layer 1: Financial Health Check

Don't just ask for financial statements – understand them. Look for consistent cash flow, manageable debt levels, and investment in equipment upgrades. A supplier struggling financially will cut corners on your order when cash gets tight.

Layer 2: Production Capacity Reality Check

Most suppliers will claim they can handle your volume. The secret is asking for their current capacity utilization and seeing their production schedule. If they're running at 90%+ capacity, your order becomes the first casualty when their bigger clients demand priority.

Layer 3: The Supply Chain Audit

This is the secret sauce. Map out their key raw material suppliers and understand their backup plans. During COVID, suppliers with diversified supply chains kept running while others shut down for months.

Secret #3: The Quality-Price Sweet Spot Formula

Here's a secret that'll save you millions: The cheapest supplier will cost you the most money in the long run.

But here's the part procurement experts won't tell you – the most expensive supplier isn't always the best either. There's a sweet spot, and it's not where you think.

The formula that works:

- Take the average of your top 5 quotes

- Look for suppliers priced 10-20% above the cheapest option

- Focus on those with proven track records in your industry

Why? Suppliers pricing 30-40% below market are either desperate (red flag) or cutting corners you can't see yet. Those priced at the very top often have high overhead that doesn't translate to better quality for you.

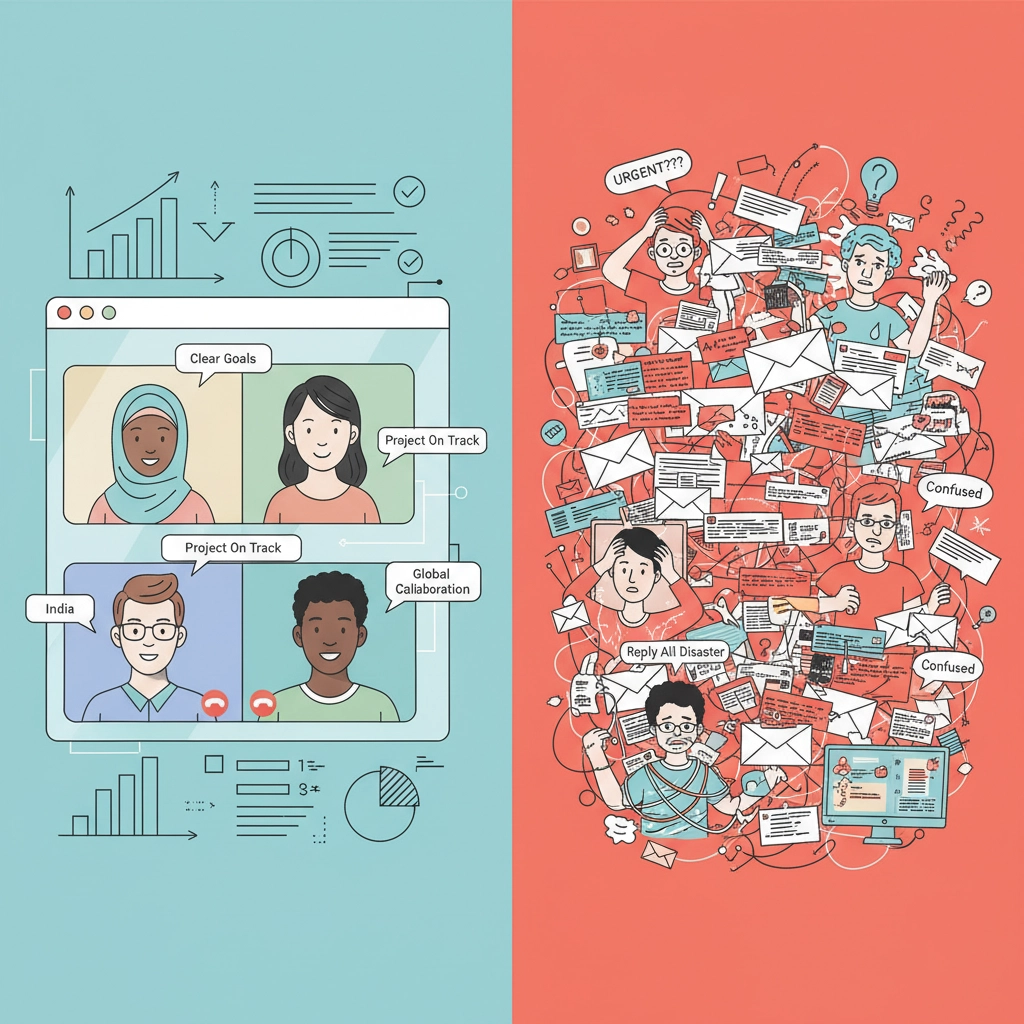

Secret #4: The Communication Framework That Prevents 90% of Problems

Most sourcing problems aren't technical – they're communication failures. Here's the framework that prevents most issues before they happen:

The Weekly Pulse Check:

Instead of waiting for monthly reports, institute weekly 15-minute calls. Ask three questions:

- What's going well this week?

- What challenges are emerging?

- What support do you need from our side?

The Escalation Ladder:

Define exactly when and how issues get escalated. Most problems stay small if caught early, but become disasters when suppliers are afraid to raise concerns.

The Cultural Bridge:

Understand that direct confrontation isn't common in Indian business culture. Learn to read between the lines when suppliers say "we'll try our best" or "it might be challenging."

Secret #5: The IP Protection Strategy That Actually Works

Everyone talks about NDAs and contracts, but here's what actually protects your intellectual property:

Compartmentalization is King:

Don't give one supplier your complete product specs. Break manufacturing into components and use different suppliers for critical parts. Even if one supplier wanted to copy your product, they couldn't without the other pieces.

The Decoy Strategy:

Include non-critical but complex-looking specifications in your drawings. If you see these meaningless features in competing products, you'll know exactly where the leak came from.

Legal Jurisdiction Matters:

Structure contracts so disputes are handled in Indian courts with Indian law. It's counterintuitive, but Indian suppliers take local legal consequences much more seriously than overseas litigation threats.

Secret #6: The Vendor Development Investment That Pays 10x Returns

Here's what procurement consultants don't want you to know: The best suppliers aren't found – they're developed.

Instead of constantly hunting for new suppliers, identify 2-3 promising vendors and invest in developing them into world-class partners.

The Development Framework:

- Share your 3-year volume projections so they can plan capacity

- Provide technical training on your quality standards

- Help them implement process improvements

- Connect them with your other preferred suppliers for knowledge sharing

One client we worked with spent $50,000 helping a supplier upgrade their quality control systems. That supplier is now their most reliable partner and has saved them over $500,000 in avoided quality issues.

Secret #7: The Pricing Negotiation Tactic That Works Every Time

Forget about aggressive price hammering – it backfires with Indian suppliers. Here's the approach that consistently delivers better results:

The Transparent Cost Breakdown Method:

Ask suppliers to break down their pricing into materials, labor, overhead, and profit. Then work together to optimize each component.

This approach:

- Shows you respect their need for reasonable profit

- Identifies real cost-saving opportunities

- Builds trust instead of adversarial relationships

- Often results in 15-25% cost reductions without quality compromise

Secret #8: The Backup Supplier Strategy That Prevents Disasters

Having a backup supplier isn't enough – you need a qualified and ready backup supplier.

Most companies maintain a list of "backup suppliers" they've never actually used. When crisis hits, these untested backups become additional problems instead of solutions.

The smart approach:

- Give 10-15% of your volume to backup suppliers during normal times

- Maintain regular communication and relationship building

- Keep them updated on your quality standards and processes

- Test their crisis response capabilities annually

Secret #9: The Quality Control System That Actually Catches Problems

Third-party inspections are good, but here's the secret weapon: Statistical process control with real-time data sharing.

Set up systems where your supplier shares production data in real-time. Monitor key parameters during production, not just final inspection. This catches problems when they can still be fixed, instead of after 10,000 defective pieces are already made.

Secret #10: The Long-Term Contract Structure That Benefits Everyone

Most companies either use short-term contracts (creating instability) or long-term fixed-price contracts (creating problems when costs change).

The secret is performance-based progressive contracts:

- Start with 6-month terms with clear performance metrics

- Gradually extend contract length as performance improves

- Include cost adjustment mechanisms for raw material fluctuations

- Build in volume commitments that benefit both parties

The Bottom Line

These secrets work because they're based on understanding that successful sourcing is about building sustainable business partnerships, not just buying products at the lowest price.

The procurement experts who guard these secrets charge premium consulting fees because they work. Companies using these strategies consistently achieve:

- 20-30% better quality metrics

- 40-50% reduction in supply disruptions

- 15-25% total cost savings (including hidden costs)

- 90% fewer supplier relationship problems

The choice is yours: keep doing what everyone else does and get the same mediocre results, or start implementing these secrets and transform your Indian sourcing success.

Your suppliers – and your bottom line – will thank you.